by Dr. Min Zhang, the EMC Consultant

One of the challenges with filters are the cost associated with high voltage and high current filter components. When the current rating exceeds 10s of amperes, the magnetic components become costly.

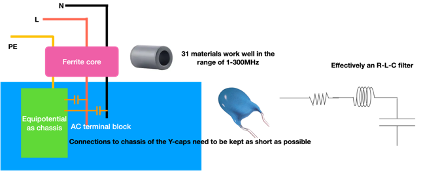

One way of implementing a cost-effective filter is to utilise magnetic cores. The ferrite cores introduced previously are just one example. Of course, the core material could be nanocrystalline or others depending on the application. Figure 1 demonstrates this concept. A ferrite, together with Y-capacitors form an R-L-C filter for the common-mode noise. The great virtue of this configuration is that the core is not subjected to saturation, so it is suitable for high current application.

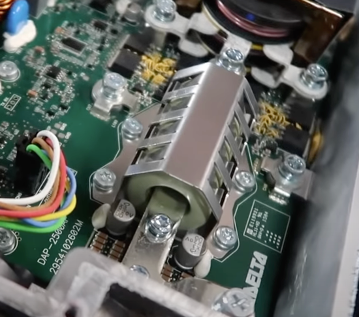

Magnetic cores are seen in many applications, such as the DC-DC converter used in Tesla electric vehicle (shown in Figure 2). The output current for this type of application often reaches beyond hundreds of amperes, any inductors on the output would be bulky, heavy and costly. Instead of placing inductors, the positive and negative rails were put on adjacent layers of the board. Depending on the current rating, often wide track or plane were used. Similar to a bifilar winding, all the magnetic field then flows in the small gap between the two planes and the only remaining flux is the high frequency common mode noise. All one needs to do then is to put a core (or multiple cores) through the board or around the board. Mechanically, this is also easy to do.

Training

If you want to learn more about EMC and become an expert in troubleshooting EMI problems. Why not attend our video training course? Priced from $199, you can get 10 hour lessons. Check https://mach1design-shop.fedevel.education/itemDetail.html?itemtype=course&dbid=1644339825702&instrid=us-east-2_4pKkzzNo1:fe56227a-47c8-4ea8-ba6f-2930d01d7db8