This section aims to elucidate the underlying testing philosophy for all EMC tests, spanning emissions, immunities, transients, and performance. Our main emphasis is on benchtop pre-compliance EMC testing, considering that design engineers are often constrained by the test equipment at their disposal.

The troubleshooting part is to introduce the skills and techniques that are essential for addressing the most challenging EMI issues. Effective troubleshooting of EMC demands a strong foundation in EMC fundamentals, a deep understanding of testing high-speed, high-frequency products, and expertise in electronics.

Video Demos

15kHz – 30MHz miniature active monopole antenna demo

Predicting Far-field radiation – A TEM cell approach demo

Predicting Far-field radiation – current probe approach

Within the engineering world, people often underestimate the value of good test engineers. A good test engineer will make sure a test lab is up-to-standard, test set-ups are correct, test procedure is strictly followed against testing standards, and most important of all, who can also support troubleshooting and get down to the bottom of an existing problem.

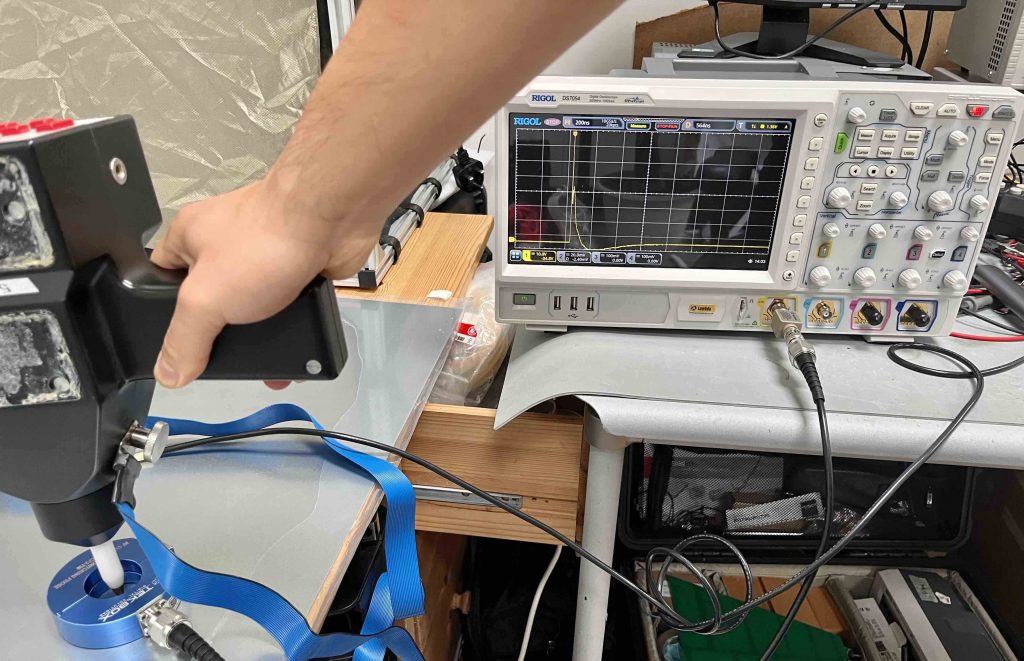

When it comes to EMC engineering, testing is perhaps one of the most important aspects. We often say “In EMC, we deal with problems in the MHz range and we fix them in millimetres.” When it comes to high frequency radio frequency signals, parasitic parameters of testing equipment and test set-up becomes very important. For instance, do you know that a ‘500 MHz high impedance’ probe doesn’t necessarily mean it can pick up signal at 500 MHz accurately? It might even fail to measure signals at 100 MHz level, since at this frequency level, the parasitic capacitance of the probe tips becomes dominant path for the signal to travel.

There are many testing standards for different industries, what do these standards mean? To what extent do these tests achieve in terms of the product’s performance? Are any of these tests related? Can we achieve cost-effective tests by our in-house test set-up? All these questions will be answered in this section.

Testing is also the first step towards troubleshooting. Once a problem is traced to its root cause by testing, troubleshooting becomes easier. Without the right test set-up, troubleshooting is simply a wild goose chase.

Written Work

Immunity Test Set-up

A Low-cost Bulk Current Injection Test Set-up

Home-made Bulk Current Injection Probe – Improved

A Capacitively Coupled Pin Injection Method-An Alternative to BCI Test

Structure Resonance Amplifies RF Noise

Emission Test Set-up & Troubleshooting

Conducted Emission Set-up and Troubleshooting – Automotive

Some details regarding to conducted emission test set-up

Conducted Emission Pre-compliance Basics

Separate common-mode and differential-mode signals

Radiated Emission Set-up and Troubleshooting – Home Appliance

Basics Test

Spectrum Analyzer Skills Must Read – How to correctly use spectrum analysers for pre-compliance EMC tests

EMC Pre-compliance Testing Guide

Ferrite Cores Basics

A Home Made Balanced Voltage Probe

Fixing and Protecting the RF Input of A Spectrum Analyzer

Measuring the Impedance vs Frequency Curve of A Ceramic Capacitor

Measuring Capacitor Array Frequency response

Video Demo

Immunity Test Set-up

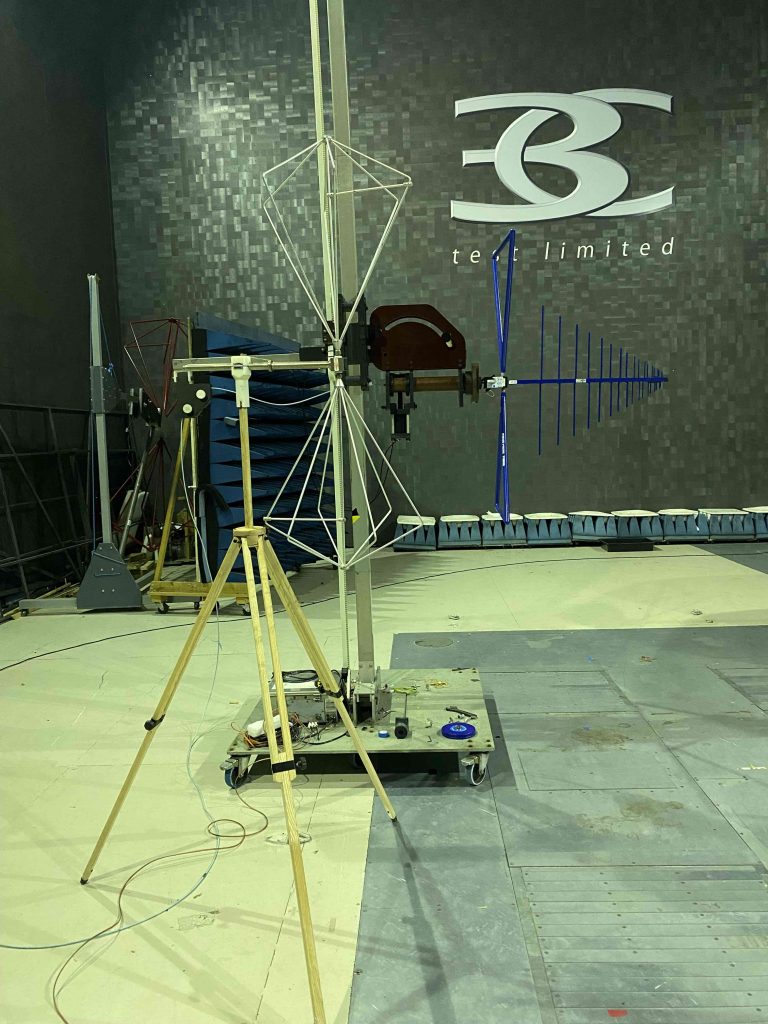

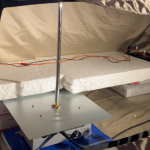

Radiated Immunity Pre-compliance Test – Simple and Easy

Bulk Current Injection Made Easy – Homemade Probe Pre-compliance Immunity Test

A Capacitively Coupled Pin Injection Immunity Test Method – An Alternative to BCI

Emission Test Set-up & Troubleshooting

Pre-compliance Conducted Emission EMC Test – Set-up, Scan and Results

Automotive Pre-compliance Conducted Emission EMC Test – Accurate results

Conducted Emission Set-up and Troubleshooting – Automotive

How to separate common-mode and differential-mode noise accurately

Basics Test