By Dr. Min Zhang, the EMC Consultant

Ferrite materials such as Manganese-Zinc (MnZn) or Nickel-zinc (NiZn) are often found in the core material of an inductor. They are also popular materials for a range of inductive components called ferrite cores (as shown in Figure 1). Ferrite cores are extremely useful in suppressing RF noise on cables. During the product development stage, they are often used for quick troubleshooting and problem fixing. For a product that is close to the market launch deadline where iteration of the board design is impossible, putting a ferrite core on cables sometimes is the only cost-effective way of getting the product pass the EMC limit.

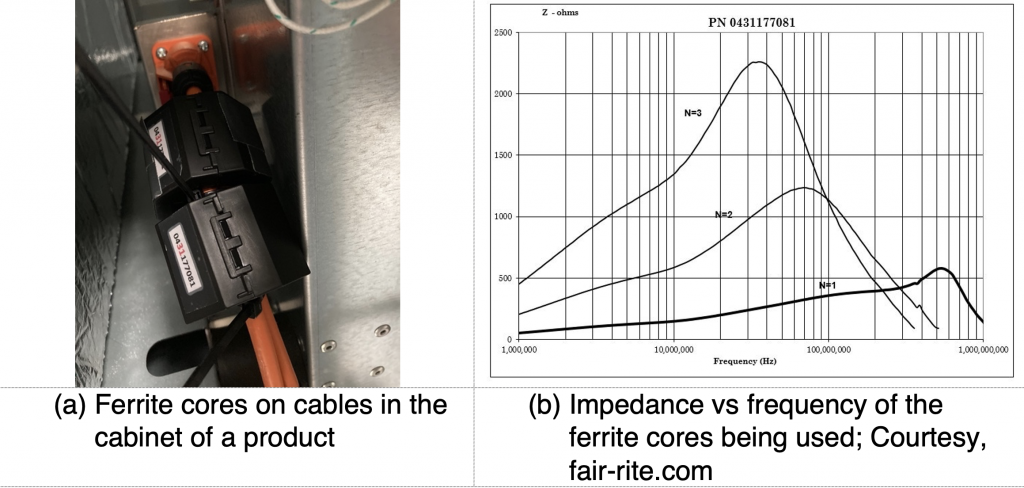

Ferrite cores can be used on single wire (as a differential-mode impedance) or a bundle of wires (as a common-mode impedance). A single-turn feedthrough configuration sometimes provides sufficient attenuation on the line. But most of the time, you might need to put multiple turns of a cable through a ferrite core so as to increase the impedance, as the impedance (inductance) value of a ferrite core is proportional to the square of the number of turns.

Engineers should be aware that although the core materials are often the same, different cores work in different frequency ranges depending on the manufacturing of these cores. Manufacturers often have specific cores for a specific frequency range. Make sure to use the right cores for the right job. For instance, if it is the medium frequency range noise between a few MHz and 30 MHz that you want to suppress, find a ferrite core whose impedance peaks in this frequency range. Figure 2 demonstrates ferrite cores on a cable (DC side) inside the cabinet of a three-phase uninterrupted power supply (UPS) system. In this case, noise level between 10 MHz and 30 MHz is quite high in the system, therefore a 31 material which works best in the same frequency range is selected to suppress the noise.

Although ferrite cores are useful for suppressing the RF noise on the cable, they cannot replace a properly designed inductor. In environments where vibration and shocks are prevalent, ferrite cores need to be secured by cable ties or other means. In applications such as automotive products, using multiple turn ferrite cores are not allowed because of the limit of the bending radius of a cable. In general, a well-designed inductor is preferred. Ferrite cores are useful as a last resort in the design and development stage or the production volume of the products is very small.