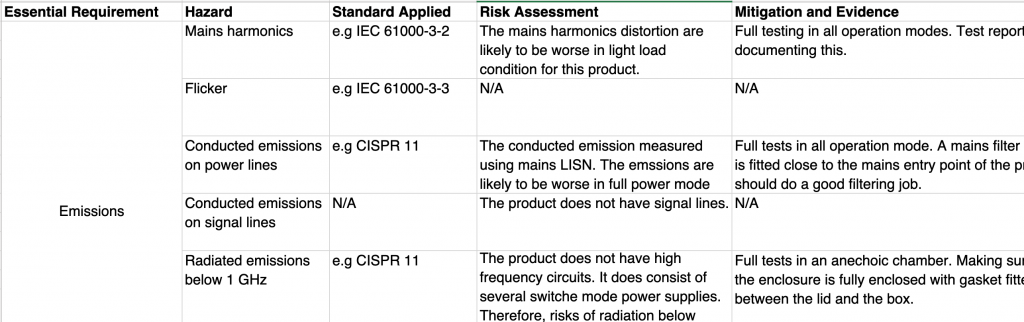

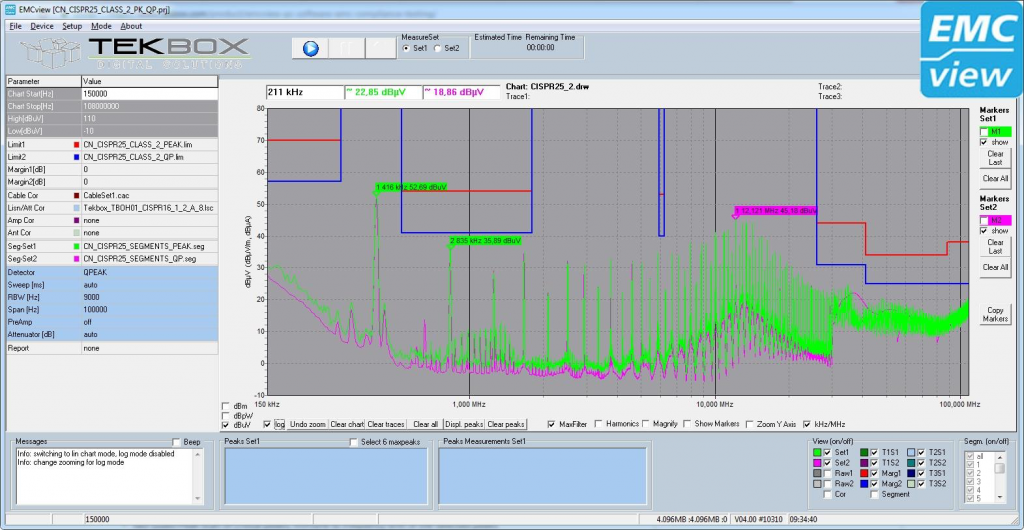

To achieve success in passing EMC tests during the initial attempt at an accredited EMC test house, it’s crucial to design the product with EMC considerations from the outset. This section delves into the designs that engineers commonly implement for effective EMC engineering.

Talks & Presentations on EMC Design

Download Essential EMC tools

Download Simulation Files

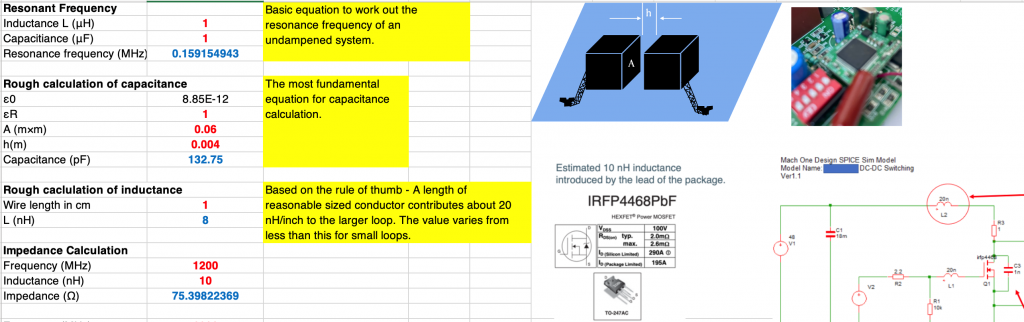

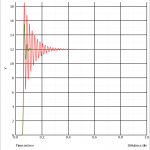

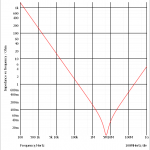

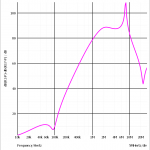

SPICE based simulations are simple and quick. We use Simetrix for most of the job. A free version of the software can be downloaded from https://www.simetrix.co.uk/downloads/download-elements.html

LTSPICE is perhaps more widely accepted by electronics engineers. Here is a good article talking about simulating conducted emissions of a buck converter. https://www.analog.com/media/en/technical-documentation/tech-articles/how-to-get-the-best-results-using-ltspice-part-1.pdf

When it comes to solving EMC issues, the best tactic really is to get the design right in the first place. In this case, prevention is much more efficient than fixing the problem. So how could we get a design right in the first place?

This section is really for design engineers (whether you are an electrical, mechanical or system engineer) who really want to get the best performance out of their systems. Getting the design right is not just for passing the legal requirement of product compliance, but also, it gives a product better performance, better power/signal integrity and longer lifetime, what we call a ‘win-win-win’ situation.

In a recent conversation with a director for the electronics department, he jokingly said “We will do a good design and rely on copper tape to do the rest!”. Joke aside, we believe any good manager would agree that getting a design right in the first place will save them lots of time and money.

In this section, we will present EMC design techniques in the product design stage. Being immersed in the global R&D departments of a few companies, we know the state-of-the-art when it comes to the design. You will find, the devil is in the details when designing a noise free system.

Presentations